Part

01

of one

Part

01

Computer Vision Case Studies

Key Takeaways

- Penn State University's manufacturing lines are saving both time and money by increasing the defect detection accuracy by 17%. The University has seen "an overall savings of $150k per production line."

- Mosaic Data Science's computer vision solution allows an energy operator to feed images into their inspection platform and save time by allowing the computer to accurately tag different parts of the infrastructure and automatically identify components that could need replacing or repaired.

- Luxoft's computer vision solution has enabled an established pharmaceutical company in operation for over 140 years to improve accuracy, faster to-market time, and increased scalability.

Introduction

This research includes three case studies outlining the application of computer vision across the industries of healthcare, manufacturing, and utilities. For each case study, the industry is noted along with what the company did, and any success metrics and statements from leadership, as available.

Mosaic Data Science: Utility Pole Inspection

- Industry: Energy/Utility

- Mosaic Data Science has worked with numerous utility clients, including NRG, Alliant Energy, Exelon, Suez, Atmos Energy, and others. As with many major case studies, the name of the specific utility Mosaic worked with is not revealed, and the company simply states that they were approached by "one of the largest utilities in the United States."

- Mosaic developed a computer vision model that automatically identified and labeled various asset types of utility equipment in inspection images in order to identify and diagnose visible defects and alert personnel to maintenance needs.

- A separate deep neural network model was developed for each asset type according to the utility's needs. A full range of model architectures were explored, including: "Single-Shot Detection (SSD), Faster Region-based Convolutional Neural Nets (FR-CNN), Retinanet, and Mask-R CNN."

- Mosaic used a dataset of 300,000+ images as source models to train the object recognition models.

- The end result of this work allows the energy operator to feed images into their inspection platform and save time by allowing the computer to accurately tag different parts of the infrastructure and automatically identify components that could need replacing or repaired.

V-Soft Digital: Manufacturing Defect Detection

- Industry: Manufacturing

- Penn State University's Department of Manufacturing needed an advanced technology solution to reduce time-consuming and costly traditional manual processes. The University turned to V-Soft Digital to develop the computer vision system.

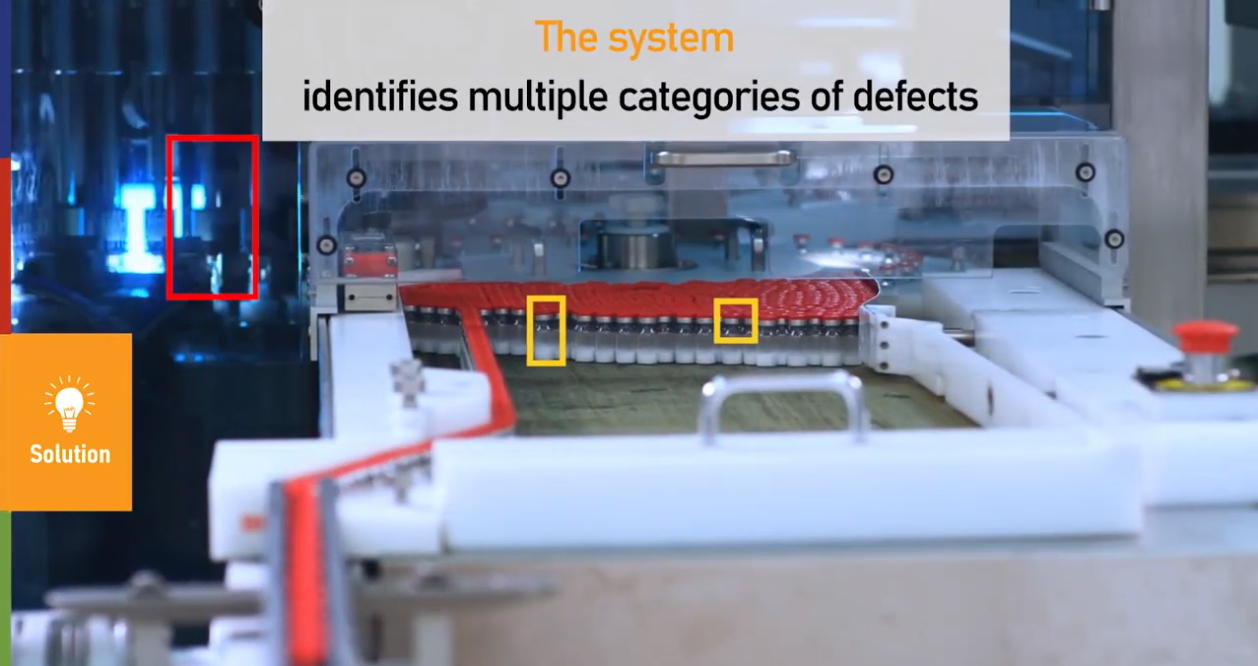

- The system deployed is able to detect defects on industrial products such as steel piping for the oil and gas industry and can categorize the type of defect.

- Senior instructor Bruce Muller from Penn State explains that if the dies for the back panels of refrigeration units are not set correctly, it could easily be an $8,000 mistake. After training the computer vision system, the algorithms got the positioning of the dies correct 100% of the time.

- The automated solution has increased the defect detection accuracy by 17% and has saved both time and money. Proactive analysis has reduced downtime by 10% and completely eliminated manual inspection. The University has seen "an overall savings of $150k per production line."

Luxoft: Dissolution Testing Process

- Industry: Healthcare

- Luxoft was approached by a leading pharmaceutical manufacturer to gauge how quickly and in what way their medicines dissolve in the body. This need is essential in order to stick to the strict requirements of the FDA. The company's current process had workers manually sifting through low-quality video footage which allowed for a high chance of human error.

- To reduce the time-consuming, potentially erroneous process, Luxoft first captured the data needed to train the computer vision models. Luxoft also fine-tuned their client's cameras by adjusting the resolution, frame rate, and bit rate. These adjustments allow for the accurate detection of abnormal situations.

- The solution provided by Luxoft has increased effectiveness and cut labor costs by avoiding innumerable hours of manual labor.

- Employing computer vision and AI has also led to faster dissolution testing processing thus allowing the client to get medicines to the market faster keeping pace with others in the healthcare industry.

- The solution allows for quality, objective data avoiding errors by human mistakes. It also allows for expansion and scale by adding new cameras, training, and AI systems.

- Gianni Piccininni, a Senior Director of Healthcare and Life Sciences at Luxoft said: “Making the change to AI and computer vision can really evolve pharmaceuticals, and the benefits are hard to pass up.

Research Strategy

For this research on computer vision in industry, we leveraged the most reputable sources of information that were available in the public domain, including Accenture, Deloitte, and several academic research resources. As is the case with many large companies and organizations when case studies are published, the company publishing the case study does not reveal who its client is. Thus, with the case studies from Mosaic and Luxoft we were unable to provide the company's name or quotes from the leadership teams. We attempted to identify both anonymous companies with numerous methods, including looking for press releases and social media references to the case studies or similar wording and phrasing as was included in the case study.